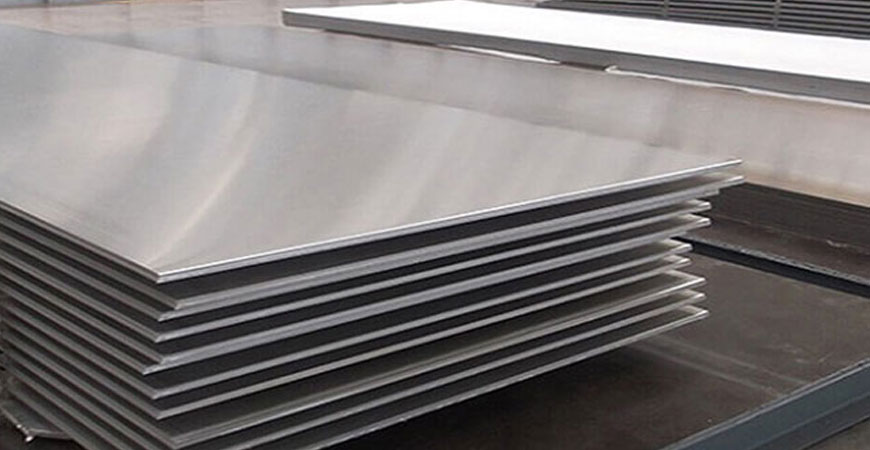

Nickel alloy plates are used in a variety of demanding applications due to their exceptional properties, including corrosion resistance, high strength, and durability under extreme conditions. Here’s a detailed overview:

Key Properties

Corrosion Resistance: Nickel alloys are renowned for their resistance to corrosion, especially in aggressive environments. They can withstand attacks from acids, alkalis, and saltwater.

High-Temperature Performance: Many nickel alloys maintain their strength and structural integrity at high temperatures, making them suitable for applications in gas turbines, reactors, and other high-heat environments.

Mechanical Strength: Nickel alloys often exhibit high tensile strength and resistance to stress corrosion cracking, which is beneficial for structural applications.

Thermal Stability: Nickel alloys are stable across a wide range of temperatures and can handle thermal cycling without losing their mechanical properties.

Common Types

- Inconel: Known for its heat resistance and strength, Inconel is used in high-temperature applications such as aerospace, chemical processing, and power generation.

- Monel: With excellent resistance to seawater and acidic environments, Monel is commonly used in marine applications and chemical processing.

- Hastelloy: Offers superb resistance to oxidizing and reducing acids, making it suitable for chemical processing and aerospace applications.

- Nimonic: Designed for high-temperature environments, Nimonic alloys are used in gas turbines and other high-stress applications.

Nickel Alloy Plate Specifications

| Specification | ASTM B162 UNS N02200, ASME SB162 |

|---|---|

| Sizes | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Length | 2m, 2.44m, 3m, or as required |

| ASTM | ASTM B168 |

| AMS | AMS 5553 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Stock in form of | Nickel Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Material | JIS: N0, N2, N1, NW2200, NW2201, NW4400, NW5500, NW6002, etc DIN:H-Ni99.96, H-Ni99.95, H-Ni99.92, H-Ni99.90, H-Ni99.5, H-Ni99, etc |

| Why choose Superior Steel Overseas |

|

| profiling | To provide a full profiling service we use numerous profiling methods including:

|

| Specialized in |

|

| Grades | Inconel 600, 625, 718, 800, 825, Hastelloy C-276, C22, MONEL 400, SMO 254, NICKEL 200/201 |

| Superior Steel Overseas offer a comprehensive menu of services designed to add value to your project: plasma cutting, waterjet cutting, laser cutting, bending and mechanical processing, edge preparation, welding, sawing and shearing. | |

Nickel Alloy Grades

| Alloy | Cr | Ni | C | Mn Max. | Si Max. | P Max. | S Max. | Other Elements |

| Carpenter 20Cb-3 | 20.0 | 35.0 | 0.06 Max. | 2.0 | 1.0 | 0.035 | 0.035 | Cu 3.5, Mo 2.5, Nb+Ta 8xC Min/1.0 Max |

| Haynes 25 (L605) | 20.0 | 10.0 | 0.05/0.15 | 2.0 | 1.0 | .... | .... | Co 50.0, W 15.0 |

| Hastelloy B-2 | 1.0 | 68.0 | 0.02 Max. | 1.0 | 0.10 | 0.04 | 0.03 | Mo 28.0, Co 1.0 |

| C-276 | 15.5 | 57.0 | 0.02 Max. | 1.0 | 0.08 | 0.03 | 0.03 | Mo 16.0 |

| Hastelloy X | 21.8 | 47.5 | 0.05/0.15 | 1.0 | 1.0 | 0.04 | 0.03 | Mo 9.0, Co 1.5 |

| Inconel 600 | 15.5 | 76.0 | 0.15 Max. | .... | .... | .... | .... | ......... |

| Inconel 601 | 23.0 | 60.5 | 0.10 Max. | .... | .... | .... | .... | Al 1.00/1.70 |

| Inconel 625 | 21.5 | 61.0 | 0.10 Max. | .... | .... | .... | .... | Mo 9.0, Nb+Ta 3.6 |

| Inconel 718 | 19.0 | 52.5 | 0.08 Max. | .... | .... | .... | .... | Mo 3.0, Nb+Ta 5.1 |

| Incoloy 800 | 21.0 | 32.5 | 0.10 Max. | .... | .... | .... | .... | ......... |

| Incoloy 825 | .... | .... | .... | .... | .... | .... | .... | ......... |

| Monel 400 | .... | 66.5 | 0.30 Max. | .... | .... | .... | .... | Cu 31.5 |

| Nichrome V | 20.0 | 80.0 | .... | .... | .... | .... | .... | ......... |

| Nickel 200 | .... | 99.6 | 0.15 Max. | .... | .... | .... | .... | ......... |

| Nickel 201 | .... | 99.6 | 0.02 Max. | .... | .... | .... | .... | ......... |

Chemical Composition Of Nickel Plates

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| N4 | 99.99 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | 99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | 99.0 | 0.20 | 0.30 | 0.30 | 0.15 | / | 0.01 | / | 0.40 |

Nickel Plates Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel Steel Plate Capabilities

| Grade | Pure Nickel Strip 99.6%/99.9% |

|---|---|

| Thickness | 0.02 to 2.50 mm |

| Tolerance | +/- 5% (special tolerances is available) |

| Width | Up to 350mm wide |

| Coil size | Up to 80kg without welds |

| Temper Ranges | Annealed to Full Hard |

Nickel Plate Stocked Sizes

| SIZE | NICKEL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | SIZE |

| 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | AL6XN | C276 | 20 | A286 | ||

| .125" | X | X | X | X | X | X | X | X | X | X | X | X | 3.18mm |

| .134" | X | 3.40mm | |||||||||||

| .156" | X | X | X | X | X | X | X | 3.96mm | |||||

| .187" | X | X | X | X | X | X | X | X | X | X | X | X | 4.75mm |

| .250" | X | X | X | X | X | X | X | X | X | X | X | X | 6.35mm |

| .312" | X | X | X | X | X | X | 7.92mm | ||||||

| .375" | X | X | X | X | X | X | X | X | 9.53mm | ||||

| .500" | X | X | X | X | X | X | X | X | X | X | X | X | 12.7mm |

| .625" | X | X | X | X | X | X | X | X | X | 15.9mm | |||

| .750" | X | X | X | X | X | X | X | X | X | 19.1mm | |||

| .875" | X | X | X | 22.2mm | |||||||||

| 1" | X | X | X | X | X | X | X | X | X | X | X | 25.4mm | |

| 1.125" | X | 28.6mm | |||||||||||

| 1.250" | X | X | X | X | X | X | X | 31.8mm | |||||

| 1.500" | X | X | X | X | X | x | X | 38.1mm | |||||

| 1.750" | X | 44.5mm | |||||||||||

| 2" | X | X | X | x | 50.8mm | ||||||||

| 2.500" | X | X | x | 63.5mm | |||||||||

| 3" | X | 76.2mm |

Nickel Plate Dimensions

| Nickel Plate Metric Dimensions | ||

|---|---|---|

| Surface finish | Thickness (mm) | Width (mm) |

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Nickel Alloy Plates Applications

Electrical Industry

Automotive Industry

Construction Industry

Defence Industry

Pharmaceutical Industry

Petroleum Industry